Get Signed Up

Masterclass Epoxy Workshop

Would you like to become an expert at working with epoxy?

This workshop is taught by the world's most experienced epoxy experts.

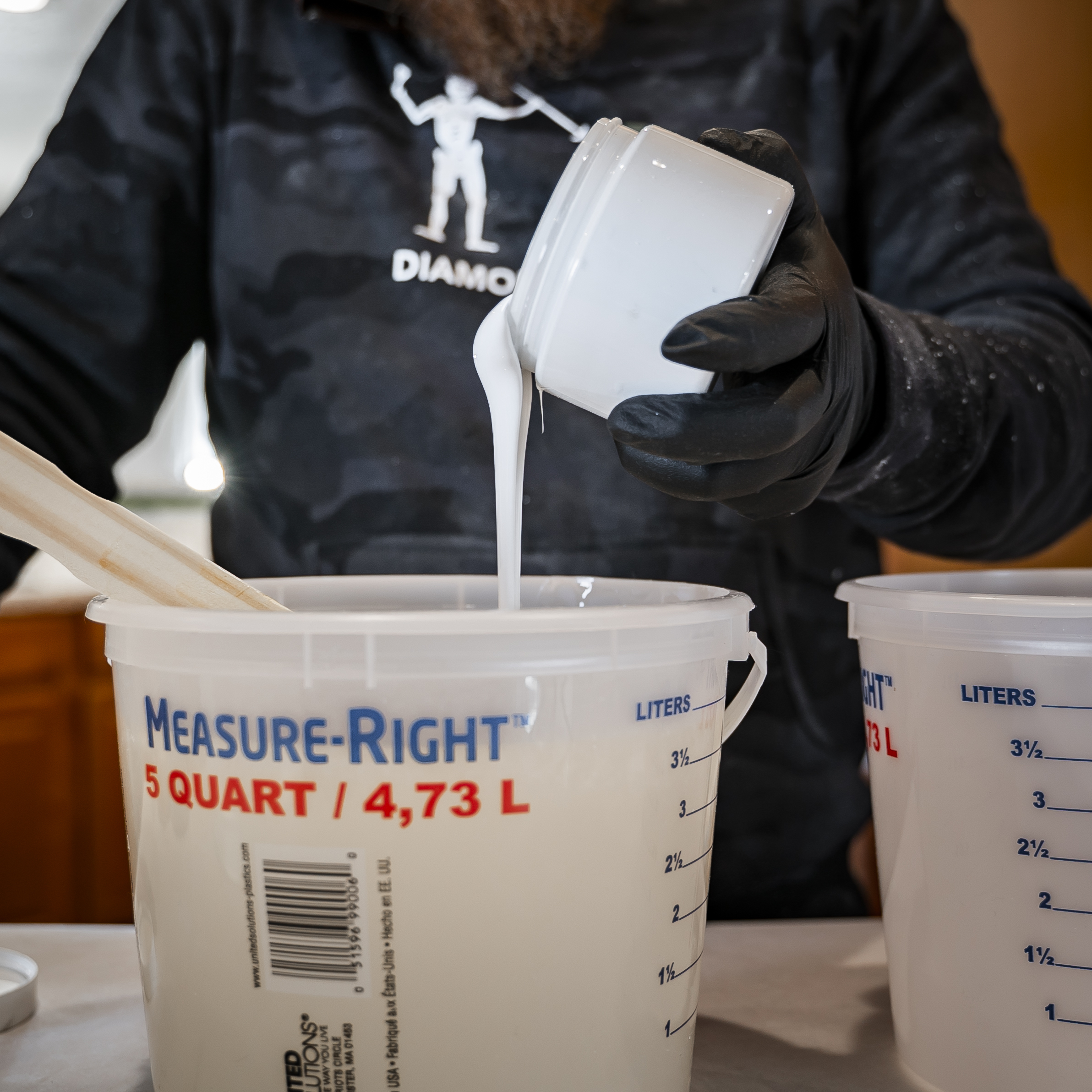

Get a comprehensive education on our; countertop epoxy, casting epoxy, wall epoxy, flooring epoxy, tub epoxy, and much more, including advanced techniques and application methods! We will go over marketing and bidding followed by a Q&A segment. In our Countertop Epoxy workshops, students will get a hands-on experience. We want you to make mistakes with our experienced staff so that we can explain the why and offer corrective options. All workshops will involve real job site pours.

After this workshop, you will have the confidence and skills to successfully install epoxy and get jobs!

Why Our Workshop Is Different

Real jobsites, real results. We don’t practice on sample boards all week. You’ll work on active installations so you learn how to prep, mix, pour, and finish in real-world conditions.

Full system training, not just techniques. We teach the entire Diamond Coat workflow: surface evaluation and repair, primers, build coats, decorative finishes, topcoats, and long-term maintenance.

Business training included. Pricing, estimating, proposals, upsells, warranty language, job scheduling, and client communication - we cover the operations that make installs profitable.

We’re not salespeople. This is a technical workshop led by installers. We teach proven Diamond Coat systems because that’s what we use in the field, and they’re designed to be repeatable, durable, and beautiful.

Lifetime discounts and tech help. After the workshop you’ll get a permanent 15% discount on all Diamond Coat Products and have ongoing support from our team for product selection, troubleshooting, and job-specific questions.

What You’ll Learn (Flooring, Countertops, Walls & More)

Substrate assessment & repair

Spalling repair, concrete patching, tile prep, leveling, moisture and adhesion mitigation.

System selection

When to choose mica flake, metallic, marble looks, solid color, and high-build resurfacing over tile or damaged surfaces.

Mixing and application

Ratios, pot life management, temperature control, working time, edge control, verticals, and seamless transitions.

Design & techniques

Veining, color layering, flake broadcast control, feathering, blending, and finishing for a premium look.

Job costing & estimating

Material calculators, labor planning, profit targets, change orders, and how to bid repair/redo projects confidently.

Client experience

Contracts, expectations, care guides, and simple maintenance plans that generate referrals and maintenance revenue.

Why Diamond Coat Systems Perform Better

High-quality, 100% solids, zero-VOC formulations for thick, consistent pours with excellent adhesion and long-term durability.

Thick-build systems engineered to resurface rough or costly-to-remove substrates (like tile or worn concrete) while delivering a premium “stone-look” finish.

Dialed-in, repeatable processes. Our systems are built to reduce callbacks and deliver consistent results across different climates and job conditions.

Expert tech support direct access to our team before, during, and after your projects.

Diamond Coat Systems

Diamond System #1: Countertops

• Epoxy basics

• Bidding and measuring

• Building new countertops vs coating existing

• Masking and protecting job sites.

• How to prep tile, laminate, stone or wood

• How to mix and add colors

• Timing and temperature

• How to create different designs working with liquid and metallics

• How to deal with verticals, edges, drains and undermount sinks.

• How to fix damaged epoxy

• How to de gloss or polish any surface

Diamond System #2: Floors

• Prepping the surface

• How to deal with settling, fractures or spalling concrete

• Moisture testing, and how to deal with moisture in a slab

• Surface grinding and prep

• Applying a Seal Coat

• Coating over different surfaces including, tile, concrete, wood, laminate, etc

• Measuring floors

• Transitions

• Cove Base Systems

• Mica Flake Floors

Diamond System #3: Supertraxx™ Outdoor Coating

• Prepping the multiple types of interior and exterior surfaces

• Fix unstable, failing or spalled concrete

• Fractures and expansion joints

• Bonding to asphalt

• Applying different Seal Coats, • Polyurethanes, and Polyaspartics

• Thin and thick-mil epoxy pours

• Traction options: Sand, traction powder, glass beads, etc, why, when and where

• Custom borders and patterns

• Cost and jobsite planning

Diamond System #4: Non-Sag

• Applying Diamond Non-Sag over different wall surfaces including tile, drywall concrete and more

• Prepping the walls floors, counters, or ceilings

• Using the Non-Sag to fill in grout lines and cracks as a preparation product as well as highly decorative and durable finishes in wet areas such as showers

Diamond System #5: Tubs and Sinks

• Prepping tubs or sinks

• High strength zero voc with endless design options

• Applying the Diamond Tub Coat to the sink or bathtub

Business Workshop

• Marketing

• Bidding jobs

• Home shows, farmers markets, and lead retention

• Connect with other installers