May 26th 2020

3 Reasons Why You Should Be Using FX Black Label

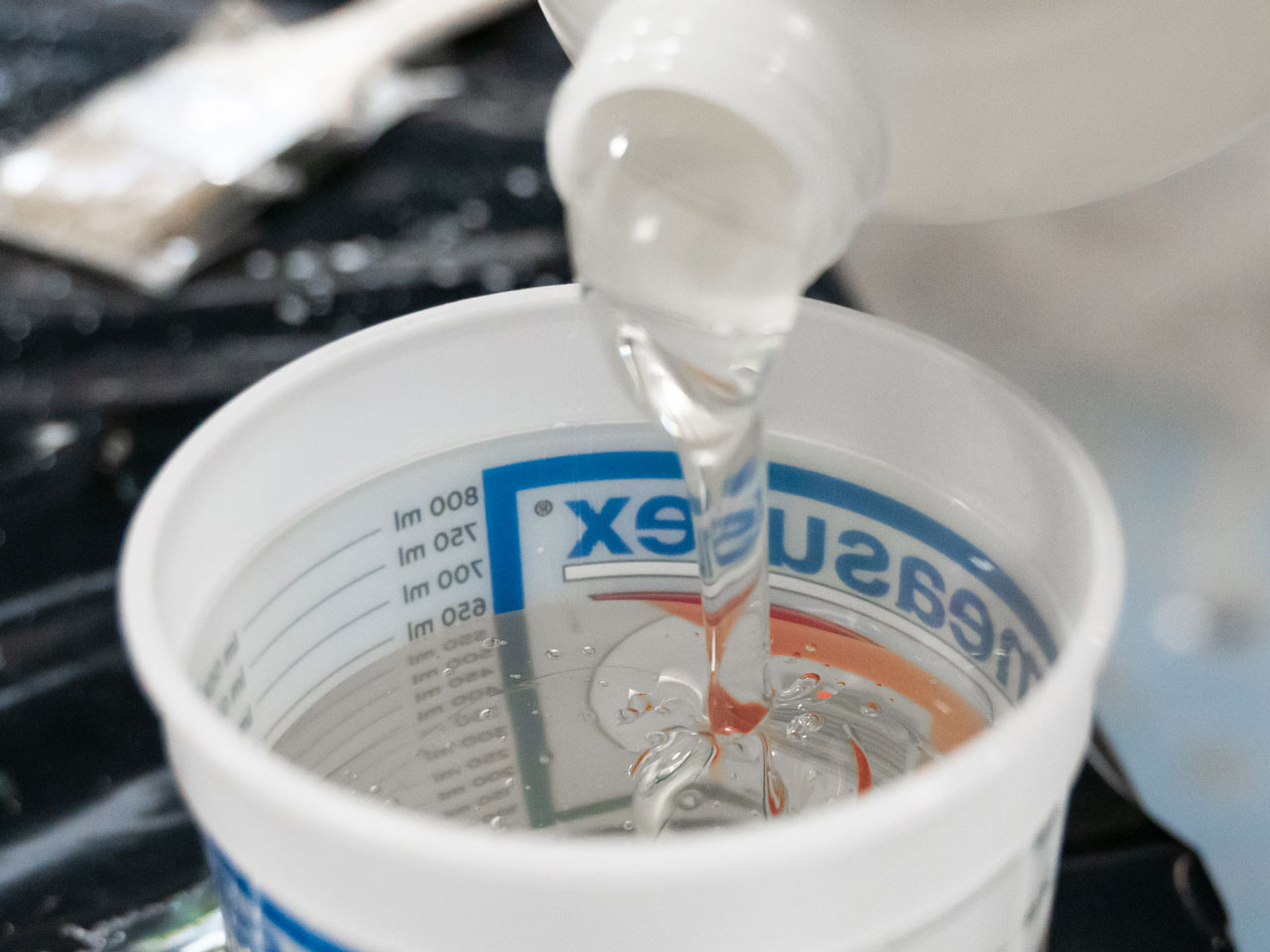

There are so many different epoxy resins on the market today, and it can be difficult to know which is right for you. Here at Countertop Epoxy, we’ve worked closely with our team of chemists to pro…

Read The Article